ROTARY DRYERS Tedrow Steam Design. Mechanism prior to design work is strongly recommended.

Xsg Series Spin Flash Dryer Changzhou Changhang Drying Equipment Co Ltd

Vertical Dryer Parameter Unit Initial Net Temperature 0C 127 O2 179 CO ppm 37 Combustion Efficiency 627 CO2 17.

. A broad range of feed materials including powders cakes granules flakes pastes gels and slurries can be processed. If the throughput of the dryer is 60 kg of wet product per hour drying it from 55 moisture to 10 moisture the heat requirement is. To design and construct a machine that will have high degree of automatization.

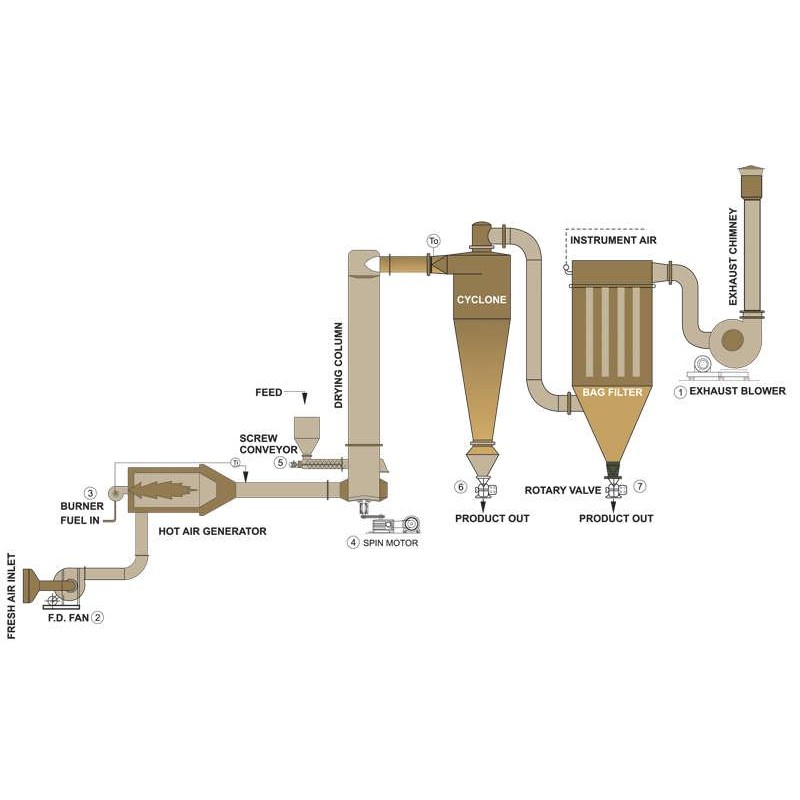

It can handle higher inlet moisture content than a standard flash dryer which for this application meant there was no need for the undesirable external recycling loop as used on other dryers to gain the product characteristics required. Or FLASH Eav 150 Eav 750 - fair good fair continuous ROTARY 10 30 15 50 indirect Eav 20 Eav 33 - poor good fair continuous ROTARY 20 60 30 100 direct Eav 40 Eav 65 - fair fair good continuous SPIN FLASH 40 18 70 300 Eav 11 Eav 185 - good good fair continuous SPRAY 03 16 5 25. Each flash dryer consists of a hot gas generator HGG a disintegrator and drying column and.

Span Flash Dryers manufactured by TRIVENI IS used for Spin Flash drying technology of high-viscosity products pastes and filter cakes Widely acclaimed by customers In a variety of industries all over India this process provides a faster and more energy-efficient alternative to spray dryingWith quite a few Spin Flash Dryer installations In India TRIVENI combines. Capacity based on 10 moisture wet weight in material fed to dryer and 326 pounds of moisture evaporated per hour for each cubic foot of the volume of the main cylinder. The flash dryers are rated at a nominal 66 tph of dry concentrate at 14 moisture while the furnace can smelt 90 tph of dry concentrate.

Vπr²L314x11²x2491m 3 82m 3 fulfill requirement Rotary Dryer Energy Balance. With more than 350 Spin Flash dryer installations world-wide SPX FLOW combines experience and cutting-edge technology into added-value solutions for our customers. Flash dryers have been used to dry products in many industries including agrifood chemical mineral.

60 kg of wet product contains 60 x 055 kg water 33 kg moisture and. Conversely when the hot air is supplied to the dryer the exhaust. A corresponding equation will have to be dX written for yet another phase gaseous and the equa- WS X1 u0002 WS X2 u0002 wD A ¼ mS 32 dt tions will be coupled by the drying rate expression.

Horizontal Dryer 2 Parameter Unit Initial Net Temperature 0C 144 O2 192 CO ppm 1 Combustion Efficiency 384 CO2 10 Flue Gas Temperature 0C 177 Ambient Temperature 0C 331 Excess Air 1061 Pressure mbar 029 Table 7. For the negative pressure or the micro-negative pressure operation the machine is good for its tightness and high in the efficiency so as to eliminate the environmental pollution. Flash drying systems use a heated carrier gas usually air to pneumatically convey the feed through the flash dryer flash tube and into a primary gas-separation device most commonly.

To design and construct a machine that will take less drying time. The feeding system includes a feed tank with agitator and a screw feeder for feeding into the drying unit. The version installed for this particular process utilizes a feed screw though some other installations have a pumped feed.

The wet material is metered into the drying chamber by a feeder pulverized and dried by stirring and vortex flow. Rotary Dryer Calculation Volume calculation. Pigment Spin Flash Dryer.

V15ms Dry Air Density. Spin Flash Dryers If the wet cake is a paste or sludge the Spin Flash Dryers are the most suited for drying application. In drying of wet solids the following main factors which essentially are used in process design calculation of dryers should be defined in accordance with mass and heat transfer principles process conditions and drying behavior.

The Anhydro spin flash dryer requires lower air flow and is therefore more energy efficient than spray dryer technology. This phase being dried in kgs this equation reads. Diameter of barrel mm Dimension mm Power kw Blowing rate m3h Water evaporation kgh GC-XSG-2.

To design and construct a machine that can dry rapidly trough spinning. For a continuous convective hot air dryer the heater duty for the inlet air heat exchanger excluding heater losses is given by. Calculation of the quantity of water to be evaporated is explained below with a sample calculation.

Product KeywordsXSG Spin Flash DryerSpin Flash DryerFlash Dryer Category Flash Dryer and Airflow Dryer Series Description The hot a ir enters into the bottom of the dryer in tangent directionUnder the driving of the stirrera powerful rotating wind area is formedThe paste s tate materials enter into the dryer through the s crew charger. The drying chamber has a rotor in its conical base that creates an efficient drying air flow pattern. We design pigment spin flash dryer for sale is a new kind of drying equipment which is developed successfully by the original flash evaporator.

This two step procedure involves disintegration about feed as well as drying of fragment feed. The dryer is fitted with a mechanical agitator which helps to disperse the wet cake without any need for back mixing of the dry powder. It adopts advanced technology reasonable design compact structure wide applicable scope large production capacity products of good quality and high efficiency energy saving.

To design and construct a spin dryer that will recycle brewery waste spent grains. G 1 AV1000W1W2100W1 3AV100055-12100-55AV956. A loop design will allow for classification and additional residence time based on moisture content or alternatively may reduce the particle size by milling the material in the dryer.

The clean thermal medium heated by the heat source enters the drying chamber in a tangential form forming a powerful vortex swirling airflow with the mechanical agitation mechanism. The Design of Spin Flash Dryer JIANG BinCHAI Ben-yinPENG Li-hua MIAO ShuaiDONG Xian-huaZHANG Lei Shandong Tianli Drying Equipment CoLtdJinan 250014China This paper introduces structure drying principles of Spin Flash Dryer and calculation and determination of related parameters. Q heater ¼ W gc PgðT gin T gaÞð15Þ HereT ginistheinlettemperaturetothedryerandT gaisthetemperatureatwhichthe air is supplied.

Widely acclaimed by customers in a variety of industries all over the world this patented process provides a faster and more energy-efficient alternative to spray drying. Therefore both flash dryers are required to operate when the furnace runs at design throughput. Spin Flash Drying is used in applications like Dryer Minerals General Chemicals and Pigments.

Has a far-reaching influence on methods of solving the model. For slurries pastes or sticky materials backmixing of the wet feed with a portion of dry product to produce a suitable. The customer furnishes and erects the brickwork setting for the dryer in accordance with drawings furnished by Equipment Company.

The Spin flash dryer consists of a feed system with a vat and agitator for buffering and fragmenting feed product. The model when represented in the form of a computer program is a valuable tool for the basic design of flash drying plant in that for given material and throughput parameter values it allows trade-offs between plant parameters such as drying column length and cross-section gas temperature and recycle ratio. Spin flash drying generates powder from the feed that is gelatinous or viscous in nature filter or paste cake.

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Request Pdf

1 Simple Flash Drying System Download Scientific Diagram

4 Spin Flash Dryer From Devahastin S Ed Mujumdar S Practical Download Scientific Diagram

Cfd Modeling Of Heat Transfer And Flow Field In Spin Flash Drying Process Springerlink

Pdf 6 Pneumatic And Flash Drying

0 comments

Post a Comment